LNG serves is considered an optimal fuel, offering significant environmental benefits, efficiency, and resource conservation. It plays a vital role in supporting national strategies for green and sustainable growth.

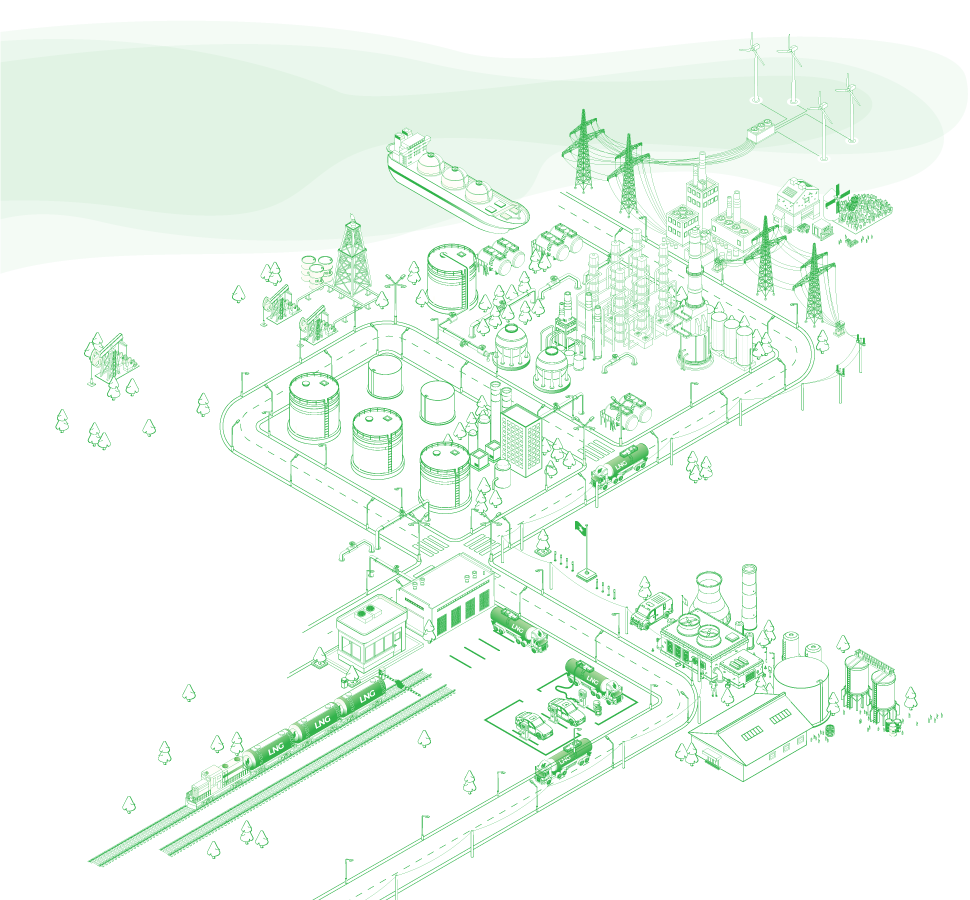

PV GAS successfully completed the commissioning and commenced the operations of Vietnam’s first and largest LNG terminal at Thi Vai in Ba Ria-Vung Tau province. This facility meets stringent international technical standards.

In addition to supplying LNG to gas power plants, PV GAS also distributes and transports LNG to industrial customers nationwide via tank trucks and gas carriers.

PV GAS produces and processes LPG at the Dinh Co and Ca Mau Gas Processing Plants, supplying 70% of Vietnam’s LPG demand from various sources including LPG produced by PV GAS, imported offshore, and from other domestic sources.

Low pressure gas is distributed via pipeline to the customers at low pressure (<49 barg).

In Vietnam, Condensate is predominantly used for producing LPG, gasoline, DO, FO, and solvents. Additionally, it is used as a key feedstock in petrochemical processing and production of olefins and BTX.

At PV GAS, we produce Condensate through our gas processing operations and distribute Condensate by means of pipeline, ship, and tank truck to our customers.

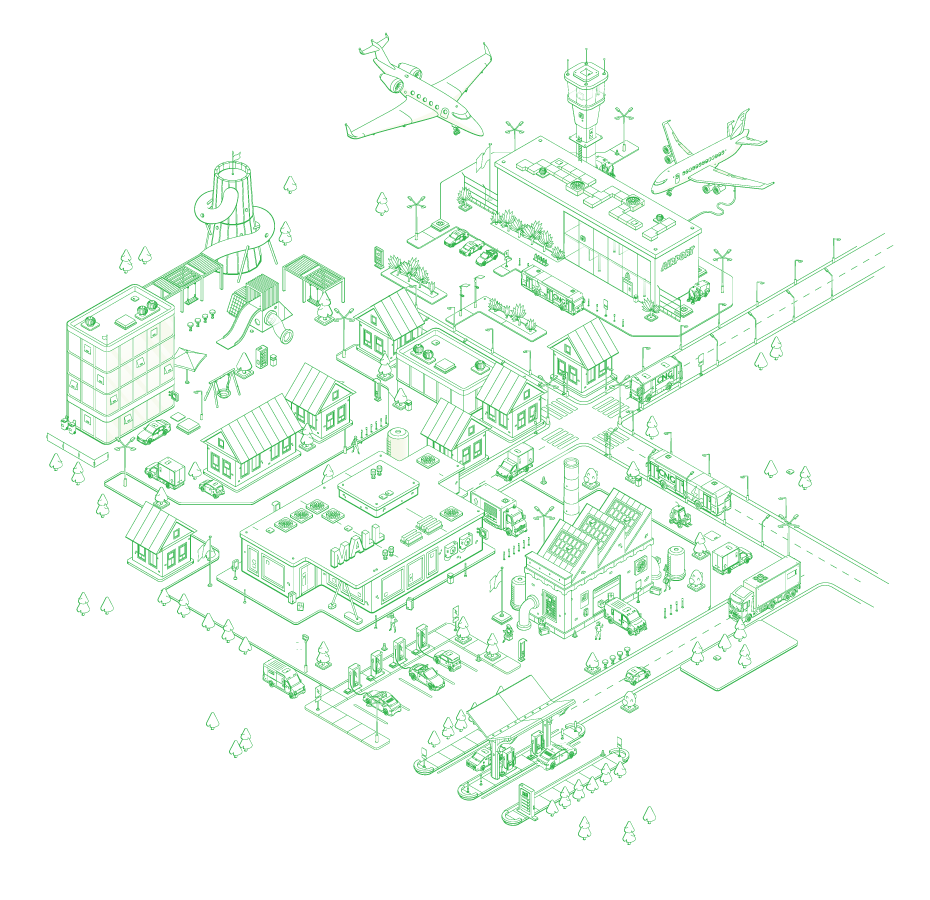

Compressed Natural Gas (CNG) is natural gas and is supplied to transportation and industrial customers located away from pipeline systems.

We offer a range of chemical products used as feedstocks in industrial production, including MDI, Sodium Hydroxide (NaOH), Sulfuric Acid, Ethylene, Propylene, and various petrol solvents.

It is utilized as a feedstock in the production of plastic resins and various other industrial applications.

It serves as a feedstock in petrochemical processing and is vital for the production of olefins, BTX, and other chemical products.

In addition to its use as a fuel, ethane is a key feedstock in the petrochemical industry, essential for producing plastics such as HDPE, LLDPE, and LDPE.

With five gas systems, comprehensive warehouse facilities, extensive pipeline network, and a fleet of tank trucks across the country, PV GAS ensures the safe, rapid, and efficient distribution of gas to production facilities nationwide.

Our terminal services include import/export operations, ship tracking, warehousing, and integrated transport solutions.

We manage the transportation of chemicals via pipeline from our terminals to customers in industrial zones. For chemicals that cannot be transported long-distance by pipeline, we provide tank storage and arrange distribution via tank truck to customers.

PV GAS offers rental services of warehouse and specialized equipment.

We provide gas transportation services as well as non-pipeline transportation for customers in and outside Vietnam. In addition, we offer full-package logistics services such as transportation, warehousing, distribution, shipping agency, etc. which suit the market demand.

We produce steel pipes for the oil and gas industry.

Our services include processing and manufacturing steel structures for industrial projects, including supports for skid clusters, piperacks, and industrial pressure tanks. We also specialize in LPG/LNG tanks for gas projects.

We manufacture structural pipes for wind turbine bases and drilling rig legs in accordance with international standards.

Our anti-corrosion coating services include coating for oil and gas pipes, renovation, repair, and anti-corrosion painting/lining. We provide fireproof concrete insulation and maintenance solutions for steel structures, pipes, and equipment used in oil and gas projects, as well as general industrial applications.

We also offer solutions for anti-corrosion, heavyweight concrete, insulation and other necessary protection solutions for steel structures.

Consultancy on Design of Gas Projects: Consulting on design of gas infrastructures including LPG/LNG terminals, LNG regasification stations, and gas supply systems for industrial zones.

Consultancy on Bidding and Evaluation: Assistance with preparing bidding documents, evaluating bids, design appraisal, cost estimation, Environmental Impact Assessment (EIA), and EPC safety management and quality control.

Consultancy on Contract Management: Supervision of contract management and implementation, including general management, quality control, scope management, scheduling, and cost control.

Liaison with Authorities: working with relevant authorities in terms of appraisal and approval related to documents on safety management, fire prevention and control, environmental protection, and maritime regulations.

Specializing in the construction of oil and gas projects and steel structures for industrial applications.

Survey, Maintenance, and Repair Services: Comprehensive services for piping systems, heat exchangers, pressure vessels, filters, tanks, separation towers, control valves, isolation valves, and safety valves. Expertise in rotating equipment including air motors, compressors, pumps, turbochargers, and expanders, as well as electrical equipment such as power supplies, generators, and UPS systems. We also handle control, measurement, and monitoring systems like DCS, SCADA, PLC, ICS, HMI, etc.

System Installation and Upgrade: Conversion, upgrading, installation, and testing of specialized gas systems and equipment.

Testing and Calibration: Services for testing, calibration, and maintenance of measurement and control devices, measurement systems and control valves.

Material and Equipment Supply: Provision of material and equipment tailored for the oil and gas industry.

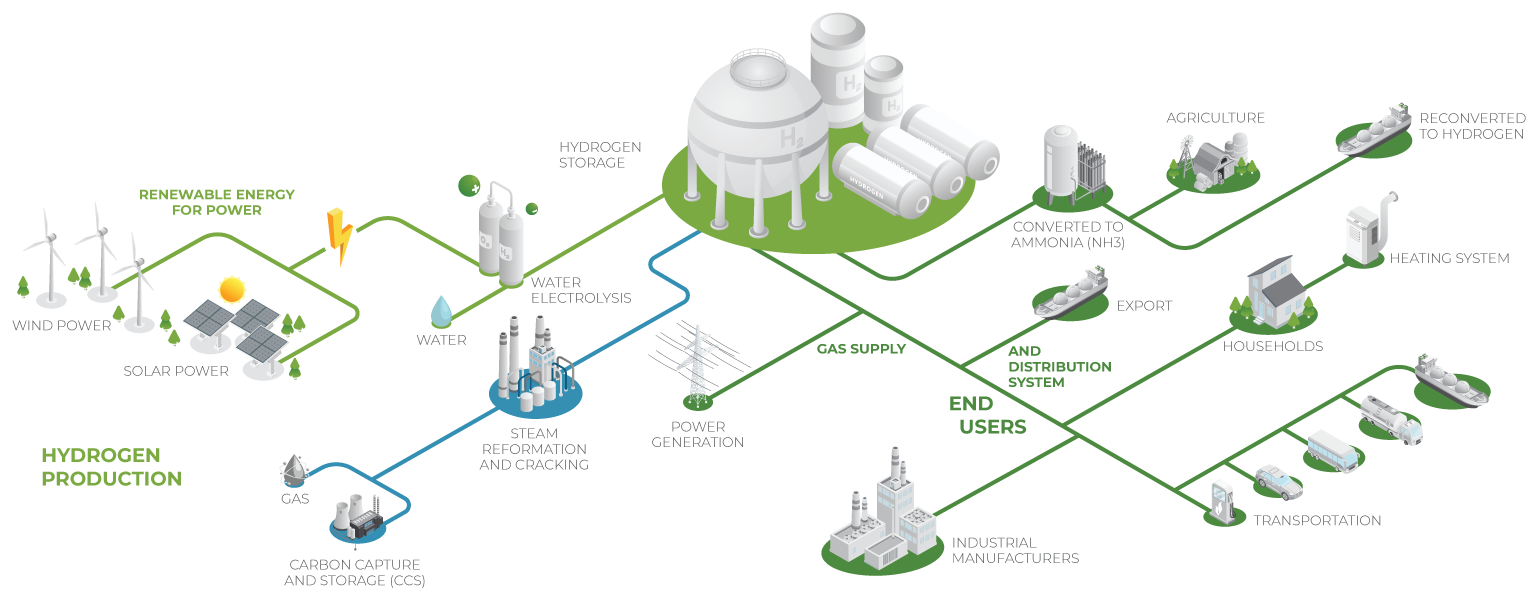

PV GAS is committed to supporting the government’s energy transition goals and achieving Net Zero by 2050. We focus on optimizing energy-efficient production and usage, embracing digital transformation, developing import and distribution infrastructure for LNG. Our efforts also include exploring innovative energy sources such as Green Hydrogen and Green Ammonia.

We are dedicated to supplying gas as a source of feedstock and participating in petrochemical projects, as well as engaging in Carbon capture and storage (CCS)/ Carbon capture, utilisation and storage (CCUS)

Green Hydrogen is produced through the electrolysis of water using renewable energy sources. It is a zero-emission fuel that plays a vital role in the global energy transition. Green Hydrogen is anticipated to be used across various sectors, including industrial production (e.g., fertilizer and methanol), transportation (e.g., hydrogen fuel cells), and power generation (e.g., electricity and heat supply).

Green Ammonia is emerging as a potential alternative to fossil fuels in the energy transition. It is produced by electrolysing water to generate hydrogen and capturing nitrogen from the air. Sustainable energy sources, such as wind and solar power, provide the necessary temperature and pressure for Ammonia synthesis. The output of the process is carbon-free Ammonia. Green Ammonia holds substantial potential in global green energy transition with zero-carbon emission and is believed to drive the global energy industry towards green and sustainable practices.